There are some customers asked “Ceramic Structured Packing and Ceramic Random Packing, which most and best used in sulphuric acid plant ? ” Before the answer , we should be know both tower packings advantages .

Let us know about Ceramic Structured Packing first .

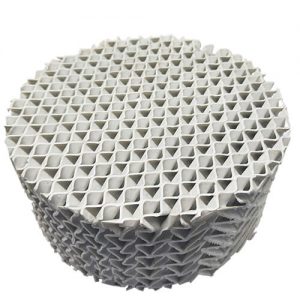

What is Ceramic Structured Packing ?

Ceramic structured packing is a type of tower packing material used in separation processes such as distillation, absorption, and stripping. It consists of thin, corrugated ceramic sheets that are stacked together to form a structured packing with high surface area to volume ratio. The sheets have a specific pattern of inclined corrugations, which creates a maze-like pathway for vapor and liquid flow, promoting efficient mass transfer and separation of components. The surface of the ceramic structured packing is coated with a thin layer of catalyst or adsorbent to enhance its performance in specific separation processes. Ceramic structured packing is known for its high efficiency, high capacity, resistance to corrosion and fouling, high temperature and pressure resistance, low pressure drop, and long lifespan. It is commonly used in the chemical, petrochemical, and pharmaceutical industries, as well as in environmental and energy applications.

The advantages of Ceramic Structured Packing

Some advantages of using ceramic structured packing include:

1. High efficiency: Ceramic structured packing has a high surface area to volume ratio, which allows for increased contact between the vapor and liquid phases. This results in more efficient mass transfer and separation of components.

2. High capacity: Ceramic structured packing has a high capacity for liquid holdup, which allows for greater throughput of fluids.

3.High resistance to corrosion and fouling: Ceramic structured packing is highly resistant to corrosion from acidic and basic environments, as well as to fouling from contaminants in the fluid stream.

4.High temperature and pressure resistance: Ceramic structured packing is capable of withstanding high temperatures and pressures, making it suitable for use in a wide range of industrial applications.

5.Low pressure drop: Ceramic structured packing has a low pressure drop, which results in lower energy consumption and operating costs compared to other types of tower packing materials.

6 .Long lifespan: Ceramic structured packing has a long lifespan due to its high resistance to corrosion, fouling, and thermal shock, resulting in lower replacement and maintenance costs over time.

What is ceramic structured packing used for?

Ceramic structured packing is used for separation processes such as distillation, absorption, and stripping in the chemical, petrochemical, and pharmaceutical industries. It is also used in environmental and energy applications such as air pollution control, CO2 capture, and natural gas processing.

In distillation columns, ceramic structured packing is used to separate components in a mixture based on their boiling points. The high surface area to volume ratio and the intricate maze-like pathway for vapor and liquid flow of the packing promote efficient mass transfer and separation of components.

In absorption columns, ceramic structured packing is used to remove impurities from a gas stream by absorbing them onto a liquid surface. The high capacity of the packing for liquid holdup allows for greater throughput of fluids, while the high efficiency of the packing promotes efficient mass transfer of components.

In stripping columns, ceramic structured packing is used to remove impurities from a liquid stream by stripping them into a gas stream. The low pressure drop and high efficiency of the packing promote efficient mass transfer and separation of components.

Then about Ceramic Random Packing .

What’s the ceramic random packing ?

Ceramic random packing is a type of structured packing material used in separation processes such as distillation, absorption, and stripping. It consists of randomly packed ceramic pieces that provide a large surface area for mass transfer between the gas and liquid phases in a column.

Ceramic random packing is often made from materials such as alumina, porcelain, or silicon carbide, which are highly resistant to chemical corrosion and thermal shock. The packing pieces are often spherical or cylindrical in shape and come in various sizes, allowing for customization to specific application requirements.

The random arrangement of the packing pieces in a column provides a high void fraction, allowing for the efficient flow of gas and liquid through the column. This results in high mass transfer rates, making ceramic random packing an effective material for separation processes.

Ceramic random packing is commonly used in applications such as gas scrubbing, acid absorption, cooling of gases, and as support media for catalysts in chemical and petrochemical processes. It is known for its high chemical resistance, low pressure drop, and ease of installation.

The advantages of Ceramic random packing

Ceramic random packing offers several advantages in separation processes, such as distillation, absorption, and stripping, including:

1. High chemical resistance: Ceramic random packing is highly resistant to chemical corrosion and can withstand exposure to a wide range of acids, bases, and solvents. This makes it a suitable material for use in harsh process environments where other packing materials may not be able to withstand the chemical exposure.

2 .High thermal resistance: Ceramic random packing is capable of withstanding high temperatures without degrading or deforming, making it ideal for use in high-temperature processes such as those found in the chemical and petrochemical industries.

3. High mass transfer efficiency: Ceramic random packing has a high void fraction, providing a large surface area for mass transfer between the gas and liquid phases. This results in high mass transfer efficiency and separation performance.

4.Low pressure drop: Ceramic random packing has a low pressure drop, meaning that it does not significantly impede the flow of gas and liquid through the column. This reduces the energy required to operate the separation process and can result in cost savings.

5 .Long lifespan: Ceramic random packing has a long lifespan, with some materials lasting for several years under normal operating conditions. This reduces the need for frequent replacement and maintenance, resulting in cost savings and improved process efficiency.

6. Easy installation: Ceramic random packing is easy to install and can be easily customized to fit specific process requirements. This allows for greater flexibility in the design and operation of the separation process.

Final Words

Both ceramic structured packing and ceramic random packing can be used in a sulfuric acid plant, but the choice between the two depends on the specific application and process requirements.

Ceramic random packing consists of randomly packed ceramic pieces in a column, providing a large surface area for mass transfer between the gas and liquid phases. It is often used in sulfuric acid plants for gas scrubbing, acid absorption, and cooling of gases. Ceramic random packing is known for its high chemical resistance, low pressure drop, and ease of installation.

Ceramic structured packing, on the other hand, consists of thin, corrugated ceramic sheets stacked together to form a structured packing with a specific pattern of inclined corrugations. It is often used in sulfuric acid plants for distillation and separation of components in the acid mixture. Ceramic structured packing is known for its high efficiency, high capacity, and resistance to fouling and corrosion.

In terms of distillation and separation of components in the acid mixture, ceramic structured packing is generally considered more efficient than random packing due to its higher surface area to volume ratio and intricate maze-like pathway for vapor and liquid flow. However, for gas scrubbing, acid absorption, and cooling of gases, ceramic random packing may be more suitable due to its high resistance to chemical corrosion and low pressure drop.

Ultimately, the choice between ceramic structured packing and ceramic random packing in a sulfuric acid plant depends on the specific process requirements and objectives.